Automation Systems

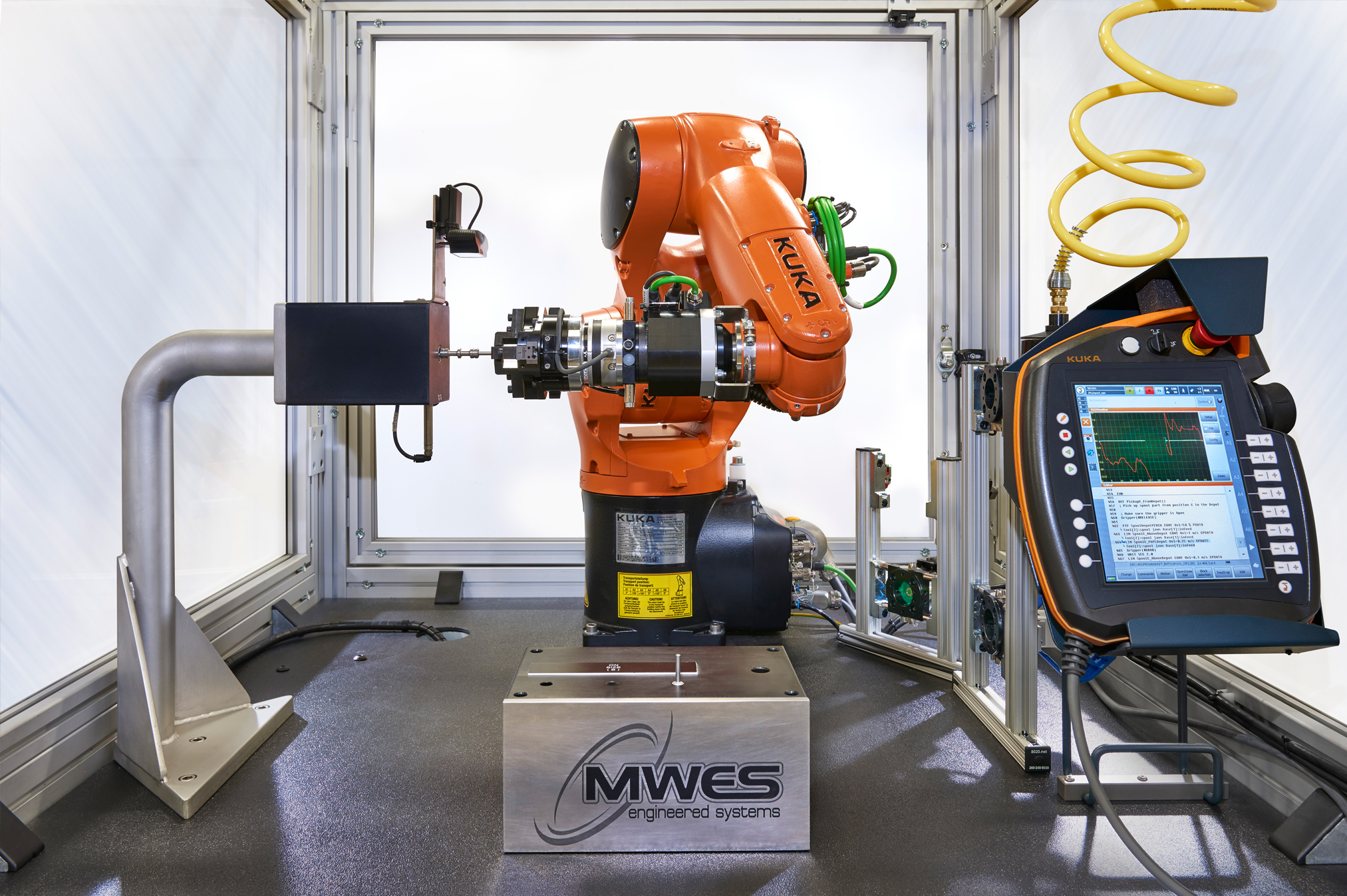

Custom Robotic Automation Systems Built to Perform

At MWES, we design and build intelligent automated manufacturing systems that eliminate repetitive tasks, enhance process repeatability, and deliver measurable improvements in quality and throughput. Whether you’re deploying a standalone robotic cell or a fully integrated production line, our systems are engineered around your specific workflow, part complexity, and performance goals.

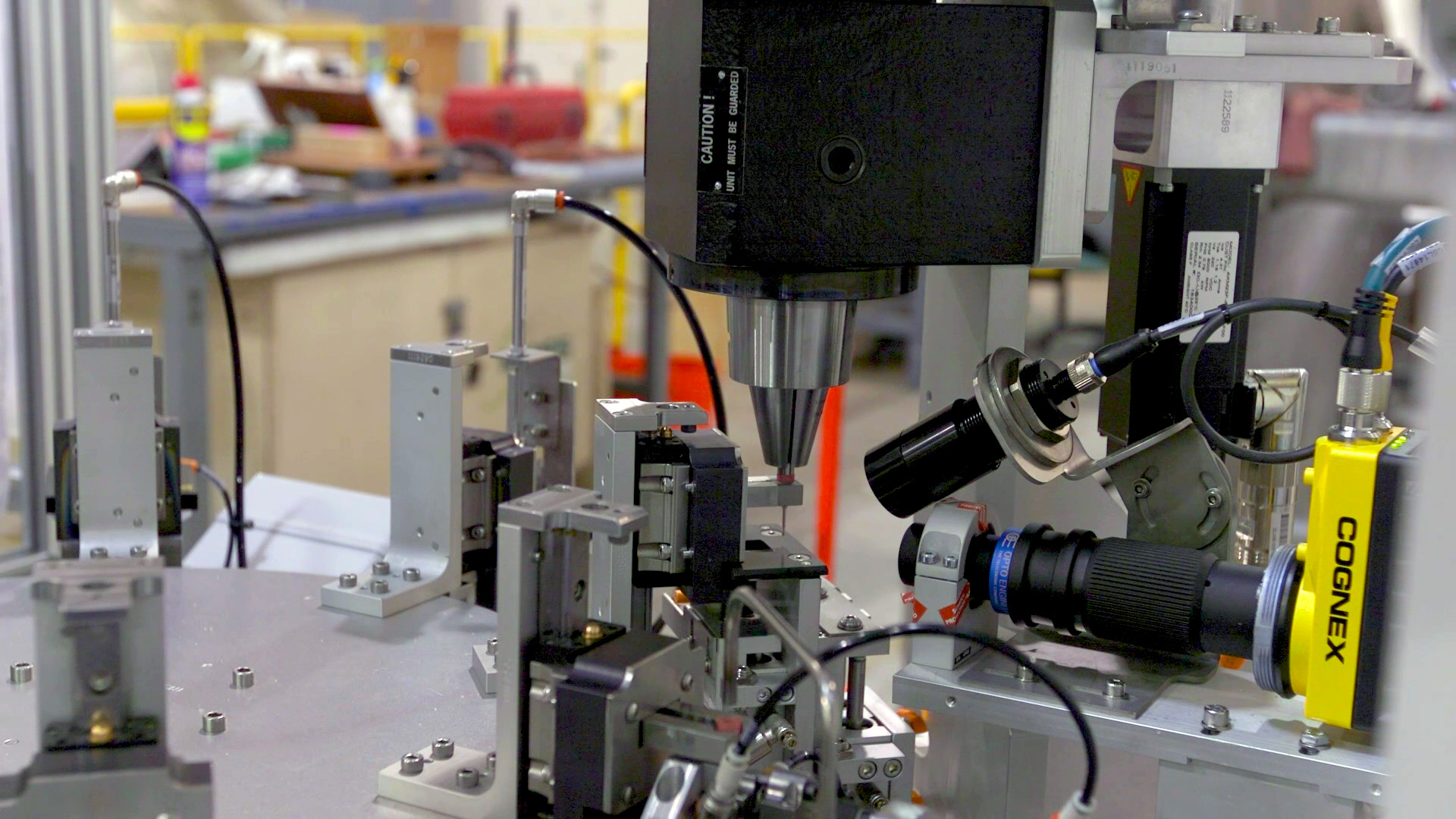

Our cross-disciplinary expertise spans industrial robotics, PLC and motion control, data acquisition, machine tending, coordinate measuring machines (CMMs), press brake automation, machining/laser cutting, paint and finishing systems, and automated packaging. By combining advanced controls with precision motion and smart part handling, we help manufacturers reduce operator intervention, increase repeatability, and meet demanding quality standards—while positioning operations for future scalability.