Collaborative robots, or cobots, are transforming manufacturing by enabling flexible automation that works safely alongside human operators. But before investing in a cobot, it’s critical to understand what to consider to maximize ROI, productivity, and safety.

Key Considerations Before Buying a Cobot

1. Task Compatibility

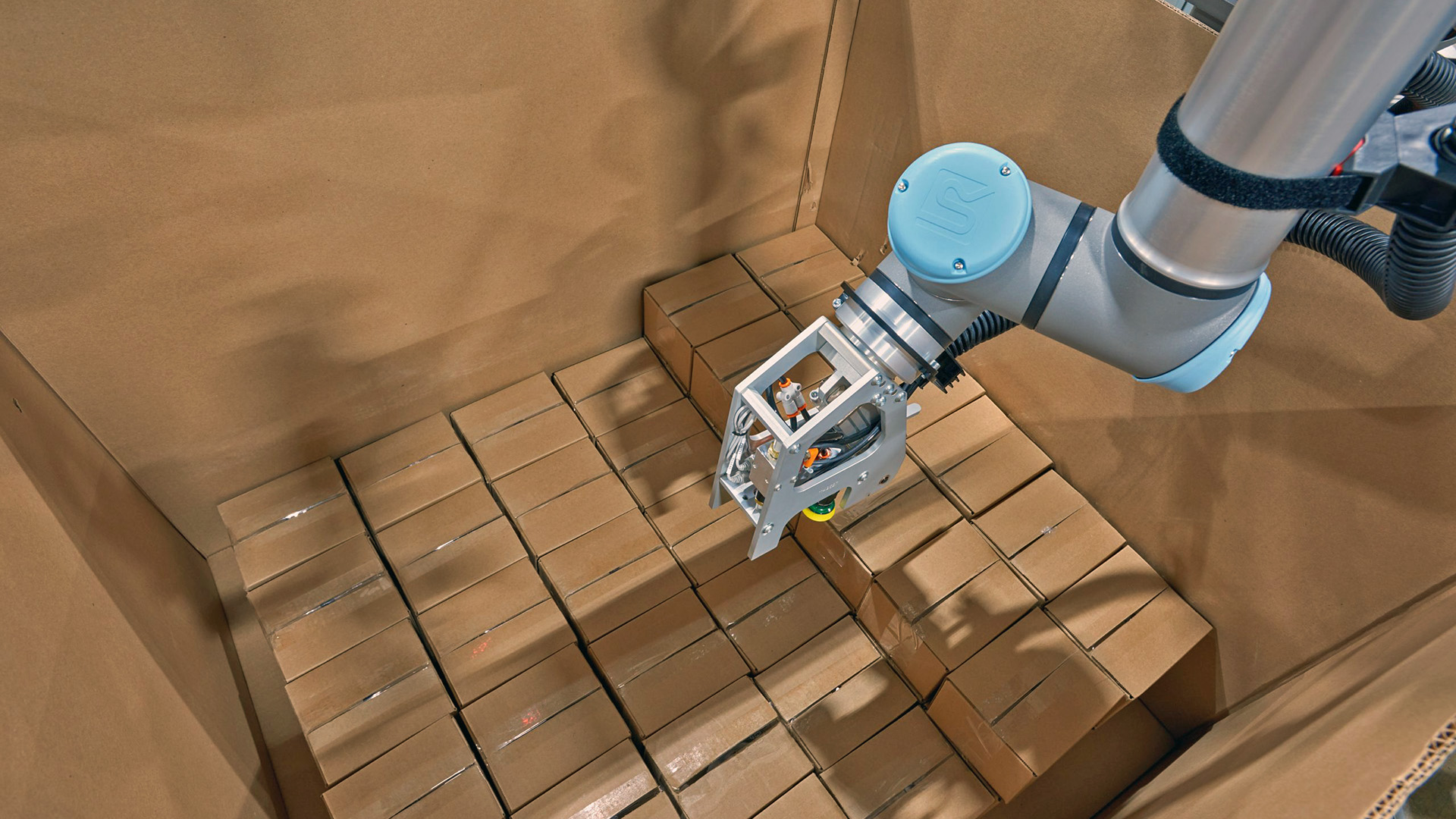

Cobots are best suited for repetitive, precise, or ergonomically challenging tasks. Evaluate which parts of your process could benefit from automation, such as assembly, machine tending, packaging, or quality inspection.

2. Payload and Reach

Each cobot has specific load capacities and reach capabilities. Ensure the cobot can handle your products and reach all necessary work areas without limitations.

3. Ease of Programming and Operation

Cobots are designed to be user-friendly, but it’s important to select one with a programming interface your team can use efficiently. Consider whether your operators require advanced coding skills or a more intuitive, touch-based interface.

4. Safety Features

Safety is a key advantage of cobots. Look for systems with built-in sensors, force-limiting capabilities, and collaborative workcell options to prevent accidents and comply with workplace safety standards.

5. Integration and Flexibility

Cobots should fit seamlessly into your existing production line, working with conveyors, fixtures, and other automation systems. Flexible cobots can be reprogrammed for different tasks, increasing long-term value.

6. ROI and Total Cost of Ownership

Assess the return on investment by factoring in labor savings, increased throughput, reduced errors, and maintenance costs. While cobots are generally cost-effective, a full evaluation ensures you’re making the right decision.

How MWES Supports Your Cobot Investment

Midwest Engineered Systems (MWES) helps manufacturers make informed decisions and implement custom cobot solutions that deliver measurable results:

- Cobot Selection Guidance: Ensure the right cobot for your application

- Custom Workcell Design: Optimize layout for efficiency, safety, and accessibility

- Programming & Integration: Seamless setup with minimal disruption to operations

- Training & Support: Empower your team to operate and reprogram cobots effectively

- Ongoing Maintenance & Optimization: Maximize uptime and long-term ROI

Benefits of Partnering with MWES

- Increase productivity and throughput

- Reduce labor strain and dependency on scarce skilled workers

- Improve quality and consistency

- Enhance workplace safety and ergonomics

- Flexible solutions that grow with your production needs

Take Action: Make Your Cobot Investment Count

Buying a cobot is more than just acquiring a machine—it’s a strategic decision that impacts efficiency, labor, and production quality. MWES ensures you select the right cobot, implement it effectively, and achieve a strong ROI.

- ✅ Schedule a Consultation

- ✅ Explore custom cobot solutions for your specific applications

- ✅ Learn how MWES can maximize efficiency, safety, and productivity in your operations

Conclusion

Understanding what to know before buying a cobot ensures your automation investment pays off. With MWES as your partner, you get expert guidance, tailored solutions, and ongoing support to successfully integrate cobots into your manufacturing workflow.