Blog & News

Check out the latest from MWES

Categories

The Return on Your Investment: Manual vs. Robotic Automation

Why would you want to use robotic automation over manual labor? Simply put robotic automation offers many benefits for your business, such as increased productivity, efficiency, quality, safety and throughput. All of these add up to substantial savings over the long term for any business that deals in manufacturing, assembly,

Welding Large Assemblies with Robotics

Welding together complex assemblies of numerous components can be done with automation – and without massive investments in systems and workforce to make it go. Many times, with proper weld fixtures, even loading and unloading the process doesn’t require a trained welder.

Streamline kitting operations for production efficiency

Keeping production on track with the right components in high variability, low volume assembly and manufacturing can be a headache that tends to affect throughput. When product variations are small in nature but important to functionality, these issues can not only affect production efficiency, it can also make trouble in keeping quality on track.

Knowing What to Automate First

When you oversee an entire manufacturing system, there’s a forest of opportunities to automate. How do you pick the first process to tackle first?

Manual Production Line Updates for Increased Throughput – No Automation Needed

Whether the human-centric production process revolves around high dexterity operations or large scale, heavy industrial applications, greater efficiency can be found by adopting systems used primarily in automation-first systems. Many times, production volume increases can be had without resulting in replacing workers with automated processes and can even be installed without large disruptions to current production.

Ways to increase automation performance without investing in a new system

Over the course of their lifetime, production line automation systems begin to lose efficiency. Replacing it with a completely new system would certainly improve throughput while bringing production tracking and control technology up to date. However, a new system’s price can be difficult to justify. Upgrade the current system, instead!

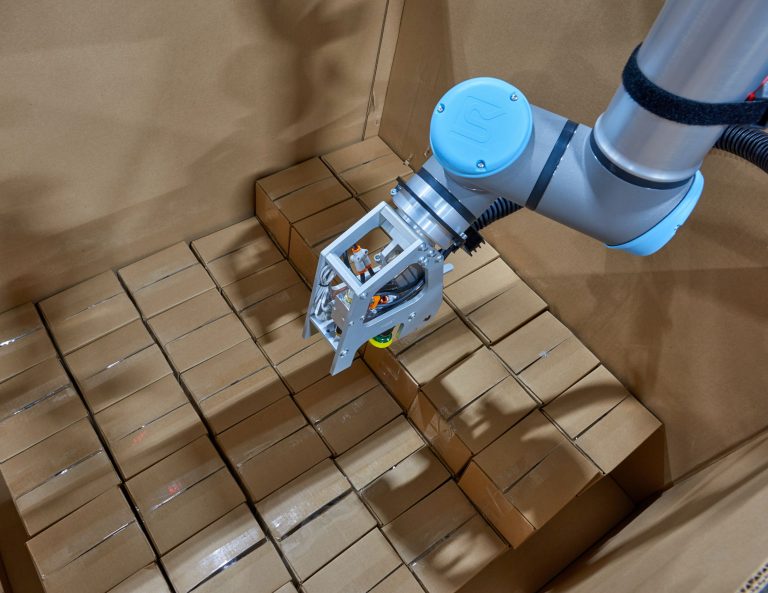

A Deeper Dive into Automated De-Palletizer Performance – Case Study

Based on using one of our turnkey de-palletizer cells, we’ve put together a case study discussing how the system helped a manufacturer reduce a large bottleneck at the front end of their production process. Within the document, we talk about its real world performance and the benefits it brings to producers who are looking to automate material intake processes.

Full Scale Integration and Abraham Lincoln

We’ve talked about big robots before, but at MWES we build the complete automation system in-house before shipping it out. That means having all the processing equipment in house as well, no matter what the scale.

Investigate automation potential with MWES’ Proof of Principle testing

For a lot of operations, the easy automation projects are essentially solved. Simple pick-place operations and general machine tending applications lead that charge with robot-in-a-box solutions. But what if you have a process that’s a lot more complex?

Universal Integrators

MWES prides itself on being independent, even when it comes down to robot selection – the core of an automation system. This allows us to offer the best solutions for our customers without being constrained. As an example, this week sees a Universal Robot getting positioned for a new automation cell build.