Flywheel Single-Station Press

- Home

- Recent Projects

- Flywheel Single-Station Press

Project summary

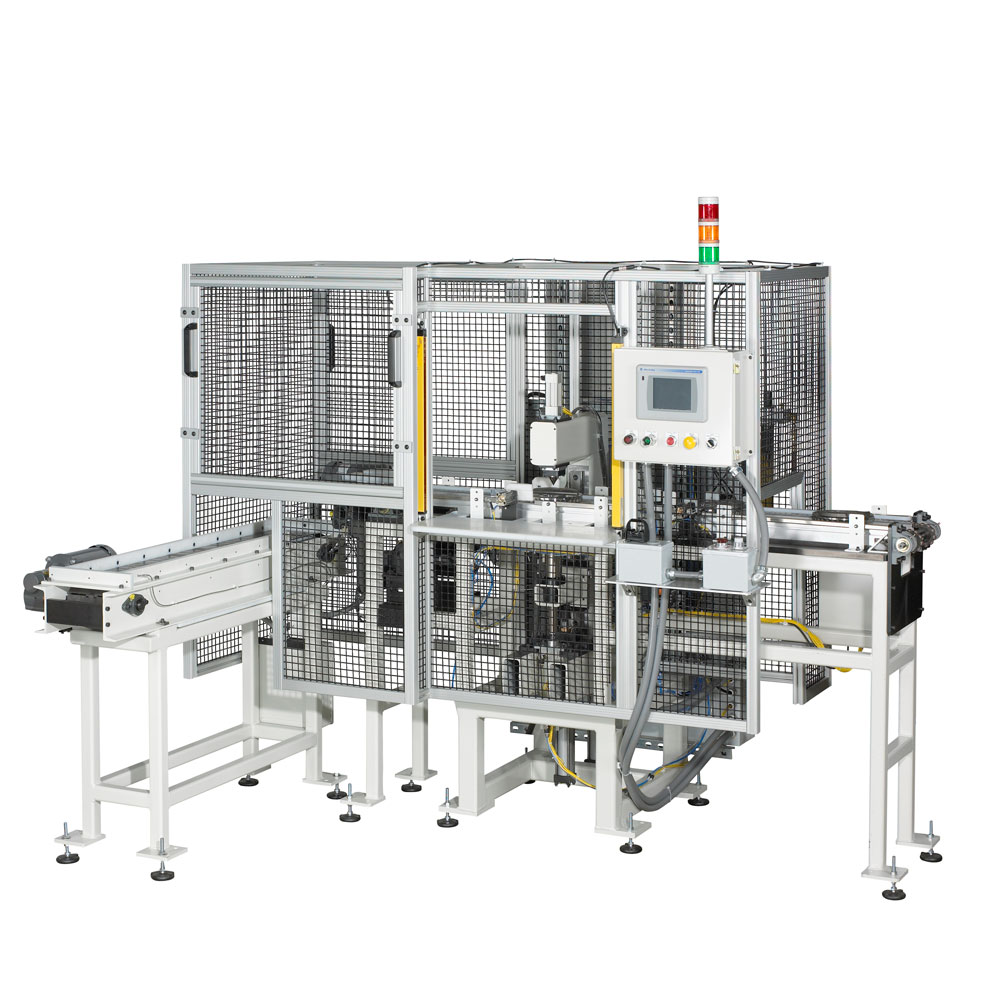

MWES provided this firm with a semi-automated assembly press machine to process individual flywheels for the manufacturing of motorcycles.

The Challenge

Assembling components in mass in any industry is a dull and repetitive task, and finding workers to do those kinds of jobs is becoming more difficult. So any opportunity to automate or even semi-automate a manufacturing process can alleviate worker shortages. A firm that specializes in motorcycle production sought out a flywheel assembly process that reduced the number of workers to perform but still required an operator to run.

The Solution

MWES provided our customer with a custom-designed semi-automated assembly press machine that performs several flywheel assembly operations. The compact machine receives flywheels on an infeed two-strand chain conveyor integrated into a parts washer conveyor for automatic flywheel introduction. The machine automatically locates the part for pressing on the center where the operator manually installs the load-bearing race. Next, at a hydraulic pressing station, the assembly is pressed using a Promess force load monitoring system for press verification feedback. Lastly, the assembled part is automatically transported to the part-flipping station where the operator manually unloads the assembled flywheel from the machine.

Impact to the Customer

The solution MWES provided the customer achieved a part rate of one part assembled every 50 seconds or less. Parts are semi-automatically assembled and all pressing is verified using Promess force load monitoring technology. Lastly, bad parts are automatically identified and singled out.

Midwest Engineered Systems has a wide range of experience in building custom automation cells. If you’re looking to improve your manufacturing throughput, we have the knowledge and experience to make the project a success.

Contact us to learn about how Midwest Engineered Systems can automate even your most complex and challenging operations today!